Brief

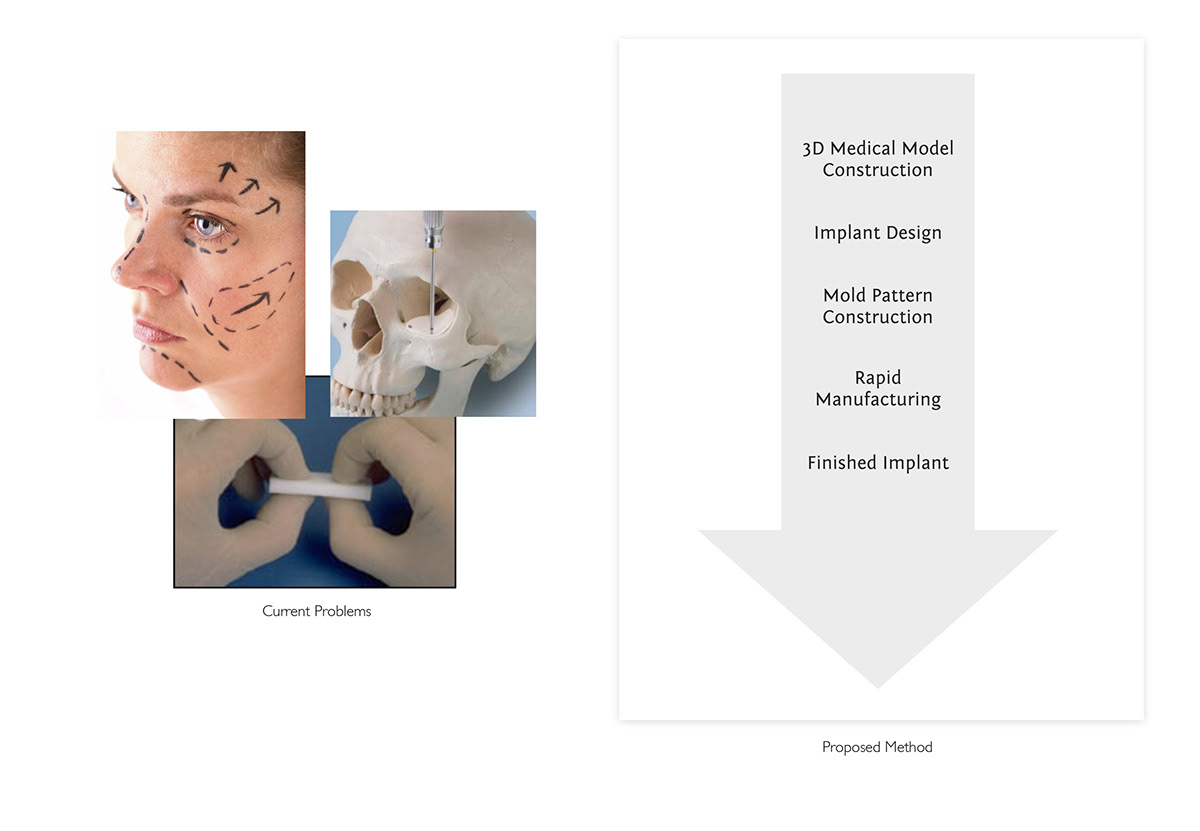

Current surgical procedures implants involve long patient waiting and evaluation times, cost of implant development and manufacturing, andsurgical treatment time. A new process to make inexpensive biocompatible implants was required.

Hence, a method of implant manufacturing using existing medical imaging, computer aided design (CAD) and rapid prototyping (RP) technologies was proposed.

Current surgical procedures implants involve long patient waiting and evaluation times, cost of implant development and manufacturing, andsurgical treatment time. A new process to make inexpensive biocompatible implants was required.

Hence, a method of implant manufacturing using existing medical imaging, computer aided design (CAD) and rapid prototyping (RP) technologies was proposed.

Process

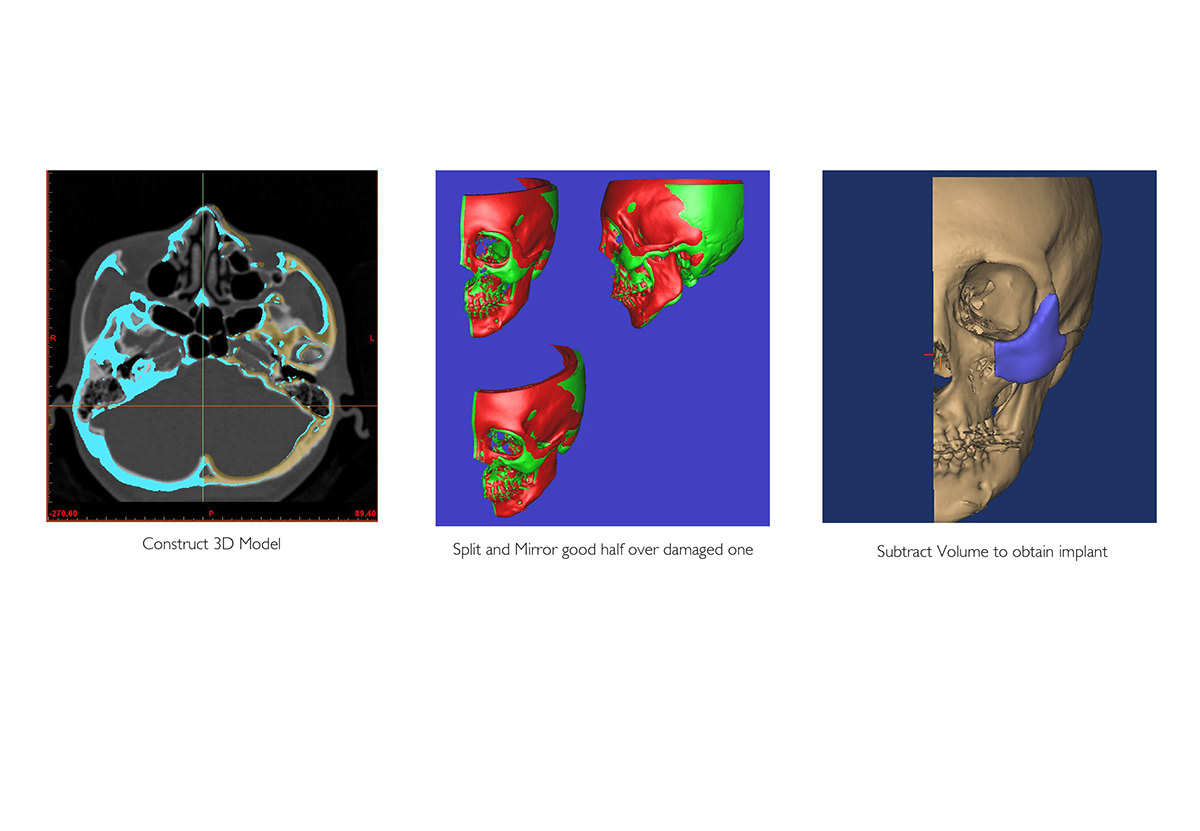

For the purpose of the case study a patient with a deformed left zygomatic bone (cheek bone) undergoing cosmetic surgery was chosen. Through the demonstrated workflow, CT scans of the patient’s skull were successfully used to construct a complete 3D skull for implant design.

For the purpose of the case study a patient with a deformed left zygomatic bone (cheek bone) undergoing cosmetic surgery was chosen. Through the demonstrated workflow, CT scans of the patient’s skull were successfully used to construct a complete 3D skull for implant design.

Design for Manufacturing

A method for manufacturing based on plastic forming was developed using rapid prototyped molds.

This process was chosen as it was easily replicable, and suitable for producing biocompatible implants in a relatively inexpensive manner.

A method for manufacturing based on plastic forming was developed using rapid prototyped molds.

This process was chosen as it was easily replicable, and suitable for producing biocompatible implants in a relatively inexpensive manner.

Implant Manufacturing

The thermoforming capability of the plastics was a key factor in their selection for the process (shown below).Based on extensive research, HDPE (High density Polyethylene) and PCL (Polycaprolactone) were selected.

The thermoforming capability of the plastics was a key factor in their selection for the process (shown below).Based on extensive research, HDPE (High density Polyethylene) and PCL (Polycaprolactone) were selected.

Finished Implants

To verify the the resulting implants from each material, the virtual model was used as the standard.

It was observed that the finished product was within the required ±0.5 mm accuracy limits

To verify the the resulting implants from each material, the virtual model was used as the standard.

It was observed that the finished product was within the required ±0.5 mm accuracy limits

Surgical Tools & Guides

Surgical Tools to assist the surgeon during surgery were also developed. The guides constructed using rapid manufacturing were able to provide timely help in the operation theater and helped reduce the surgery time to as low as 15 mins.

Surgical Tools to assist the surgeon during surgery were also developed. The guides constructed using rapid manufacturing were able to provide timely help in the operation theater and helped reduce the surgery time to as low as 15 mins.